SUSTAINERA RECYCLING PROCESS

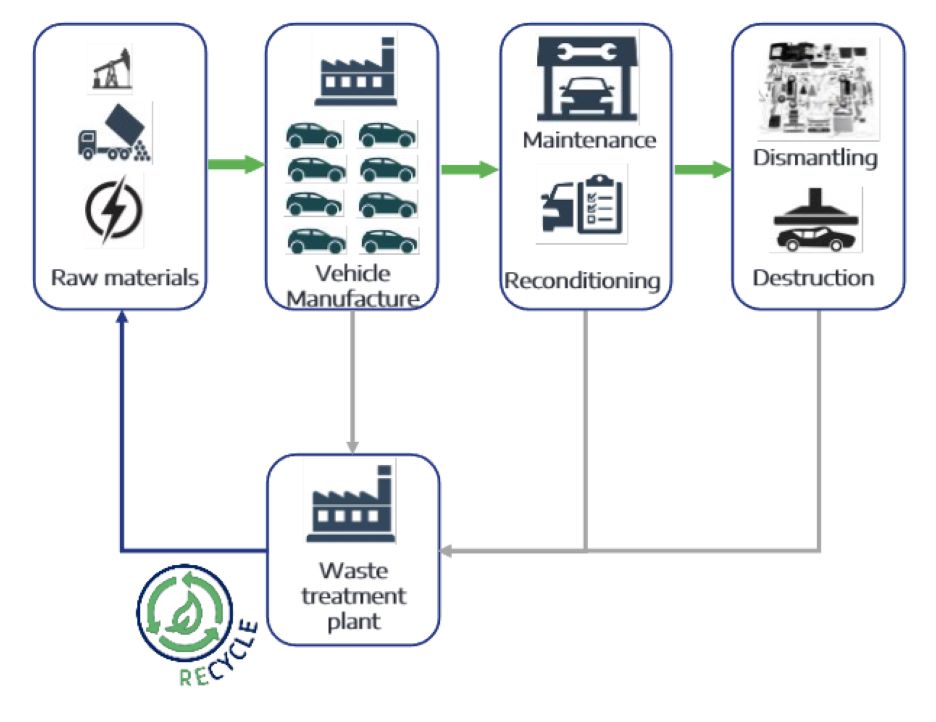

Recycled parts and materials from production, maintenance scraps and ELVs (End-of-Life Vehicles) fed back into the manufacturing process

of new vehicles and aftersales products.

of new vehicles and aftersales products.

SUSTAINera RECYCLE

Recycled parts and materials from production, maintenance scraps and ELVs (End-of-Life Vehicles) fed back into the manufacturing process

of new vehicles and aftersales products.

of new vehicles and aftersales products.

In a context of the increasing scarcity of natural resources, to limit the impact of overuse and reduce waste, we recover and recycle materials from production, maintenance scraps and End-of-Life Vehicle processing, then return them into the manufacturing loop for new vehicles and new parts or reuse them outside the automotive sector.

This way, we close the loop via the efficient circular economy model, to ensure a sustainable business model and reduce demand for new raw materials.

RECYCLE

Product Range

SUSTAINera’s innovative approach in the automotive parts sector represents a significant stride toward sustainability. Our RECYCLE products, which meet stringent specifications, expand our after-sales range. Our products are suitable for Stellantis vehicles and other brands, ensuring performance without compromise while minimizing environmental impact. By integrating material recovery solutions and a robust recycling process, SUSTAINera supports a sustainable business strategy focused on the responsible recovery of materials, driving long-term sustainability in the automotive sector.

Made from regenerated recycled fluids, industrial production waste, or former products, our RECYCLE items exemplify our commitment to environment-friendly practices. By choosing SUSTAINera RECYCLE products, you actively participate in the Circular Economy, benefiting both the environment and future generations through resource conservation, material recovery, pollution reduction, and sustainable business practices.

Enlarged Europe

Recycle Fluids

Recycle Oils

WATCH THE VIDEO

Recycle 12V Battery

WATCH THE VIDEO

Recycle Batteries

LEAD BATTERY

EV & PHEV TRACTION BATTERY

Recycle Body

WINDSCREEN

Enlarged Europe

Recycle Fluids

Recycle Oils

ENGINE LUBRICANTS

Recycle Batteries

LEAD BATTERY

EV & PHEV TRACTION BATTERY

Recycle Body

WINDSCREEN

CAR RECYCLING

DISCOVER how to recycle your car safely, easily and sustainably.

High-Voltage Batteries Recycling

High-Voltage Batteries from electric vehicles that cannot be remanufactured, repaired or reused, are recycled in selected recycling facilities.

The recycling process involves components being mechanically shredded to obtain a black mass, that is then treated to extract main raw materials (like Li, Co, Ni, Mn, Al, Cu ) which are then used to create brand new batteries for future EV vehicles.